Call us Today : 011 452 8883

: 071 897 5978

Follow us!

15a main Road

Eastleigh

Edenvale

1609

Home

About Us

Products

Specials

Size Guidelines

Contact Us

Heatshrink -

Thermofix's XLP thin wall Heatshrink Tubing is a Chemically Cross-

The heatshrink can easily be shrunk with a heat gun or a heat tunnel. All heatshrink in this range is flame retardant.

Highly flexible

Flame retardant

Abrasion and impact resistant

For use in all electrical and electronic applications as well as telecommunications

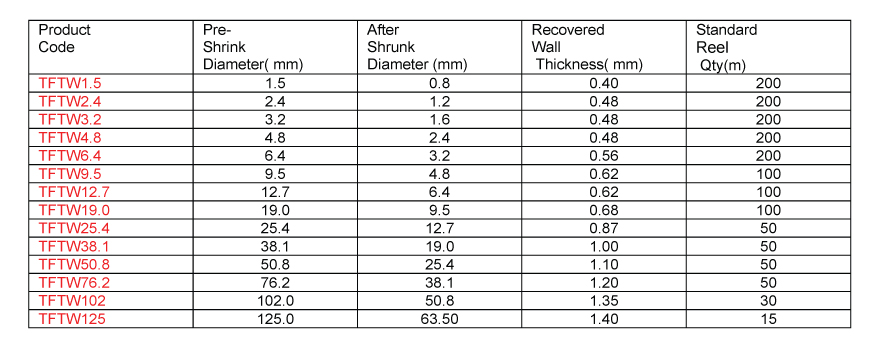

Full range 1.5mm to 125mm diameter with 2:1 shrink ratio

Available in most colours on reels.

Thermofix's XLP heatshrink tubing has numerous uses in the electrical and associated industries, including insulation, colour coding and mechanical protection.

Ul224 VW1 File no E204071

Chemically cross-

Flame retardant polyolefin

-

>100°C

<5%

14 MPa

25 Kv/MM wall thickness

1.0 x 10 (14) ohm cm

600%

0.15% max

Passed

600V

**Yellow only available in 2.5 / 3.2 / 6.4 / 9.5 / 12.7 / 19.0 / 25.4

**XLP125 only available on request.

Technical Data

Compliant Standards

Material

Continuous Operating Temp

Shrinkage Temp

Longitudinal Shrinkage

Tensile Strength

Breakdown Voltage

Volume Resistivity

Elongation at Break Point

Water Absorption

Flammability

Voltage Rating

Printed heatshrink -

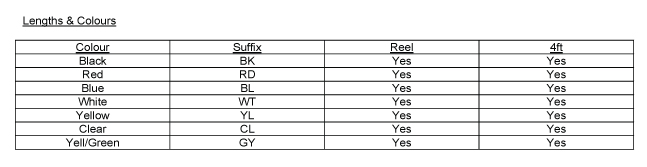

Thermofix's XLP thin wall Printed Heatshrink Tubing is a Chemically Cross-

All heatshrink in this range is flame retardant.

Highly flexible

Flame retardant

Abrasion and impact resistant

For use in all electrical and electronic applications as well as telecommunications

Full range 1.5mm to 125mm diameter with 2:1 shrink ratio

Available in white, red. blue and yellow

Thermofix's XLP printed heatshrink tubing has numerous uses in the electrical and associated industries, including insulation, colour coding and mechanical protection and most importantly for the identification of cable, wire, ropes and harnesses. Apply a clear heatshrink over the label for a protective sleeve for outdoor use.

**Lengths and Colours Available

Your printed heatshrink can be blue, red, white or yellow. The print is in black and can be alpha, numeric or both. Custom designs are also available to suit logo's etc

Technical Data

Compliant Standards

Material

Continuous Operating Temp

Shrinkage Temp

Longitudinal Shrinkage

Tensile Strength

Breakdown Voltage

Volume Resistivity

Elongation at Break Point

Water Absorption

Flammability

Voltage Rating

UL224 VW1 File no. E204071

Chemically cross-

Flame retardant polyolefin

-

>100°C

<5%

14 MPa

25 Kv/MM wall thickness

1.0 x 10 (14) ohm cm

600%

0.15% max

Passed

600V

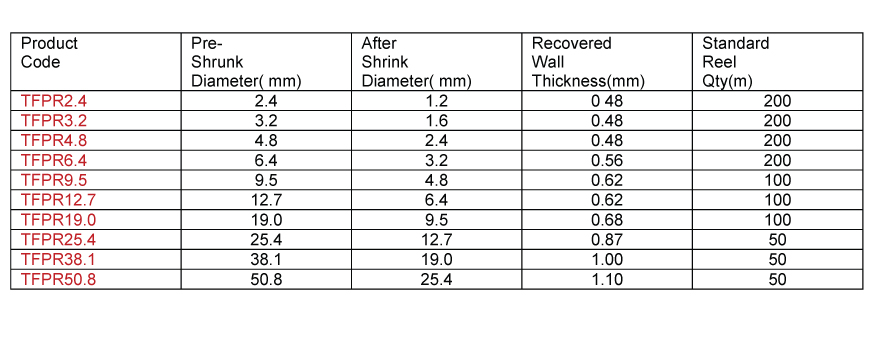

Glue Lined Heatshrink -

TFADW is a Thin Walled Heatshrink Tube with a Glue Lined inner surface. It is made from a dual extrusion of polyolefin and adhesive. It is commonly referred to as 'dual walled .

Highly flexible

Very high shrink ratio 3:1

Flame retardant

Good mechanical adhesion

This is a heatshrink with many applications in the electrical and mechanical protection areas Since the glue holds the tubing in place it is commonly used for brake and fuel pipe protection in the automotive industry. Typical electrical applications are strain relief on cords, and insulation repair. In general this heatshrink is not recommended for waterproofing since the glue layer is primarily a mechanical adhesion and is thin.

Use Thermofix's TFMDW medium wall heatshrink for fail safe waterproof Joints

Technical Data

Meets Sony Standards

Conformant Standard

Material

Continuous Operating Temp

Shrinkage Temperature

Tensile Strength

Elongation at Break Point

Longitudinal Shrinkage

Dielectric Strength

Volume Resistivity

Water Absorbtion

Flammability

Voltage Rating

UV Resistant

SS-

UL 125°C VW-

Dual Wall, flexible, flame retardant (Except Clear)

-

Starts at 80°C -

10.4MPa

200%

0 to-

20 Kv I mm wall thickness

1.0 x 10 (14)ohm cm

<0.5%

All tubing flame test Pass

600V

Yes

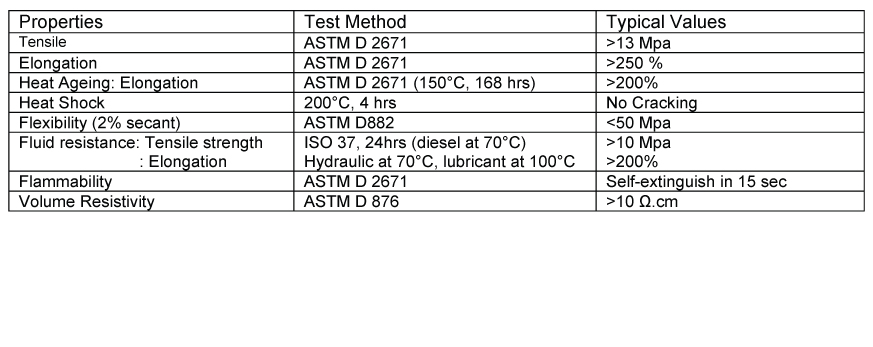

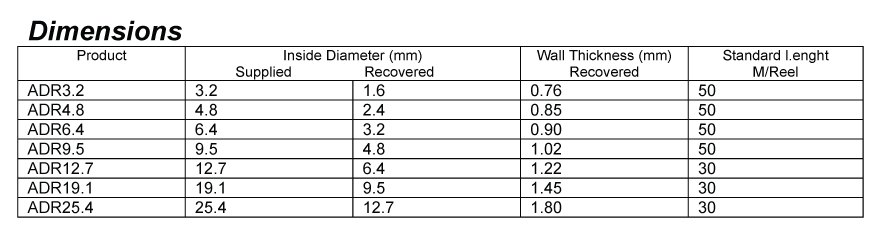

Diesel Resistant Elastomeric Tubing

Description

DR/25 has superior diesel, chemical and abrasion resistant properties. Its formulation also makes it suitable for use in areas where it requires extended exposure to high temperatures and fluids.

Applications

Automotive wiring harnesses

Applications that requires superior abrasion and temperature resistance combined with flame retardancy as required in military vehicles

Features

Shrink Ratio 2:1

Crosslinked modified elastomer

Operating Temperature -

Superior abrasion resistance

Flame retardant

Highly Flexible

Excellent temperature and fluid resistance

Colours -

Minimum fully recovered shrink Temperature, 175°C

Meets: SAE-

RoHS compliant

UV Resistant

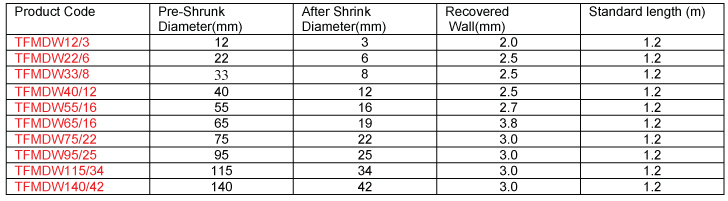

THERMOFIX Medium Wall Heatshrink

Thermofix Medium Wall is adhesive lined cross linked polyolefin Tube which is primarily used for waterproof jointing and sealing cable terminations. The hot melt liner creates a strong bond between the cable jacket and the tube. This keeps it water, weather and dirt resistant. It can be used on joints from 1 Kv to 36Kv. It has excellent impact and abrasion resistance. The product is a 3:1 shrink ratio and is only available in Black. It is UV Resistant.

Cost Effective and quick waterproof jointing

High Shrink Ratio

High rigidity and tensile strength once shrunk

Resistant to Decay, chemicals and corrosion

Thermofix TFMDW Medium Wall Heatshrink -

Technical Data

Conformant Standards IEC

Material

Continuous Operating Temp

Shrinkage Temperature

Tensile Strength

Elongation at Break Point

Longitudinal Shrinkage

Dielectric Strength

Volume Resistivity

Water Absorption

Flammability

UV Resistant

VDE.ASTM

Cross Linked Polyolefin with Thermoplastic

mastic sealant

Note Unlined tube may be ordered (no sealant)

-

Fully Recovered 120°C

> 14MPa

400%

0 to -

> Kv I mm wall thickness

10 (14)ohm cm

<0.15% -

Do not use TFMDW in flame prone areas

Yes

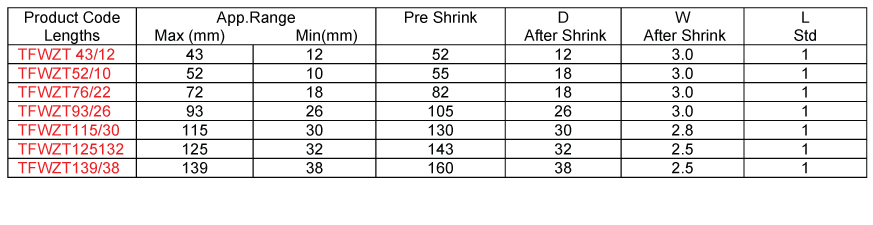

Thermofix -

TFWZT. Zipper Tube is a Cross-

Ideal for on site field installation

Jointing in tight areas

Re-

100% waterproof and low water absorption

Quick start up time after completing joint

Repair of un pressurised pipes

Non meltable

Resistant to decay, chemicals, corrosion

Installation recommendations are virtually the same as for TFMDW. When applying heat, check that carbonisation or crazing does not occur and do not apply heat directly onto the stainless steel channel. When shrinkage has been completed, the stippled effect on the tube surface will not be noticeable since Thermochroic paint has changed colour

Technical Data

Conformant Standard

Material

Continuous Operating Temp

Shrinkage Temperature

Tensile Strength

Elongation at Break Point

Longitudinal Shrinkage

Dielectric Strength

Volume Resistivity

Water Absorption

Flammability

UV Resistant

IEC; VOE; DIN

Cross Linked Polyolefin with hot melt

Adhesive lining & stainless steel channel

-

Starts at 105°C and complete at 125°C

17 MPa (excluding channel)

350% (excluding channel)

10%

12 Kv I mm wall thickness

1 Ox 10 (16)ohm cm

0.1%

Do not use in flame prone areas

Passed-

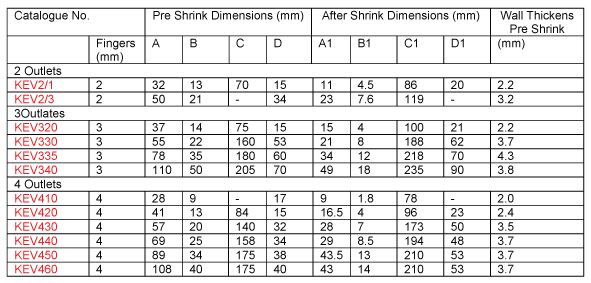

Thermofix Heatshrink – Boots

Heatshrink Boots are used to seal and waterproof cable terminations, by sealing the insulated conductors to the cable jacket

They have a hot melt glue liner which melts while the boot is shrinking and creates a strong bond between the boot and the cable.

Quick and simple installation of waterproof termination

High resistance to tearing and high tensile strength

Resistant to decay, chemicals and corrosion

To select a boot, measure the outside diameter of the cable and order the next size up by checking dimension 'A' in the accompanying table. To install the boot, ensure that the insulation of the cable and conductor are clean and grease free, and roughen with emery paper for a good glue bond. Shrink the boot from the middle out with a heatgun or soft yellow gas flame until adhesive extrudes. Avoid local overheating during shrinkage process.

Technical Data

Conformant Standards

Material

Continuous Operating Temp

Shrinkage Temp

Tensile Strength

Elongation at Break Point

Breakdown Voltage

Volume Resistivity

Water Absorption

Flammability

UV Resistance

DIN: VDE· IEC

Modified cross-

-

Starts 105°C, completed 125°C

18 Mpa

450%

Longitudinal Shrinkage

10%

16 kV/mm wall thickness

1.0 x 10 ohm cm

0.15%

Do not use KEV in flame prone areas

Passed -

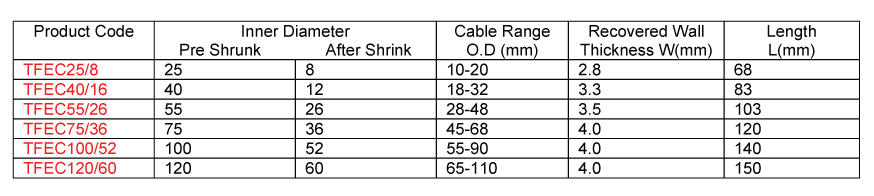

Thermofix Heatshrink End Caps

Thermofix's Heatshrink End Caps are used for sealing cable ends during installation or storage. They are made from cross-

Quick reliable seal of cable ends

Watertight and unlimited storage life

Highly resistant to ultraviolet rays, aggressive soils, chemicals and corrosion

Capping of Hydraulic and Pneumatic tubes to prevent ingress of both dust and moisture

The TFEC Heatshrink cap should be shrunk onto the cable end starting the shrinkage from the closed end. Once shrink is complete glue should extrude from the edges of the cap.

Technical Data

Conformant Standard

Material

Continuous Operating Temp

Shrinkage Temperature

Tensile Strength

Elongation at Break Point

Longitudinal Shrinkage

Dielectric Strength

Volume Resistivity

Flammability

UV Resistant

IEC: ASTM

Cross Linked Polyolefin with thermoplastic

Mastic sealant

-

120°C

12 Mpa

>400%

10%

15 Kv I mm wall thickness

1.0 x 10 (14) ohm cm

Do not use in flame prone areas

Good

| Heatshrink |

| Braided Sleeving |

| Terminals |

| Securing |

| Lugs/ Ferrules |

| Glands |